Pine Point Mine Hydrogeology and Water Management

Problem

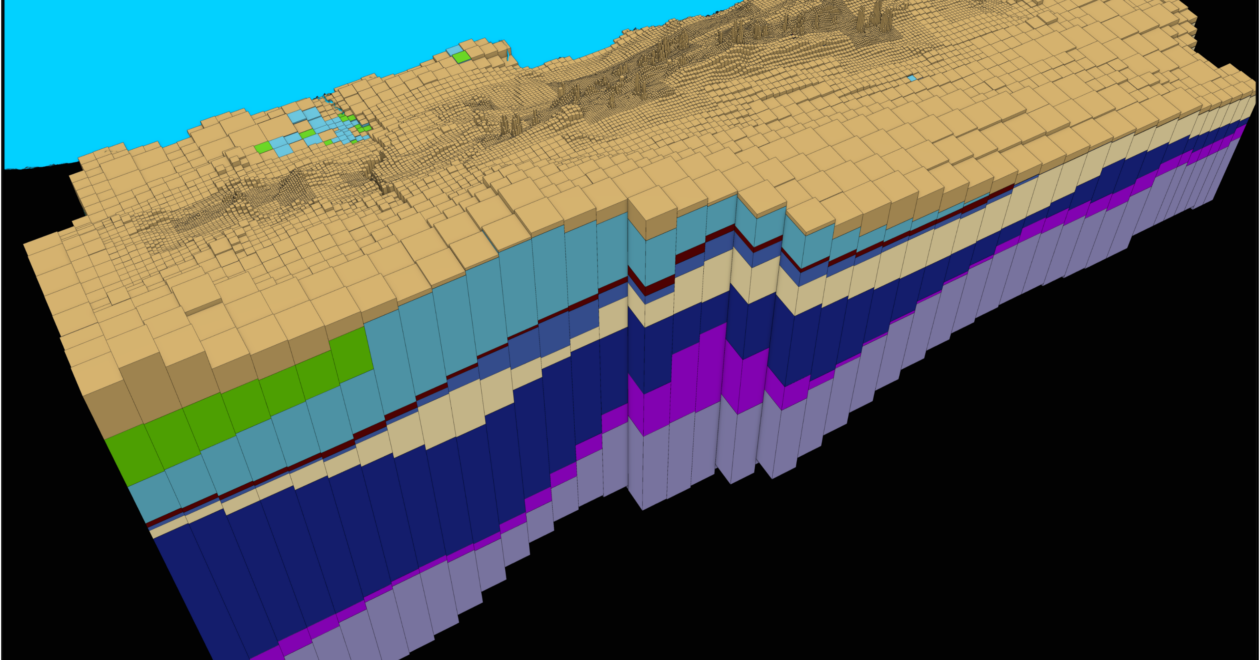

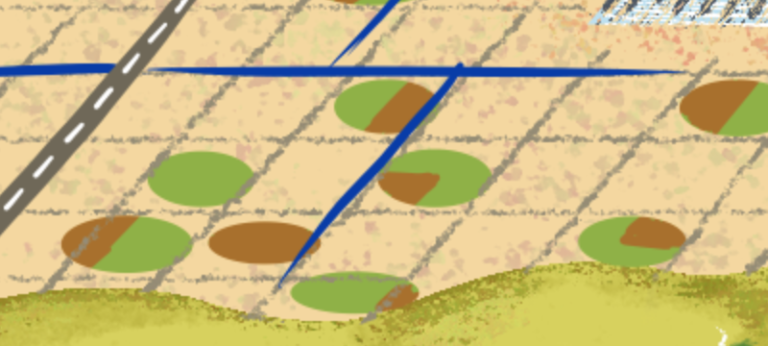

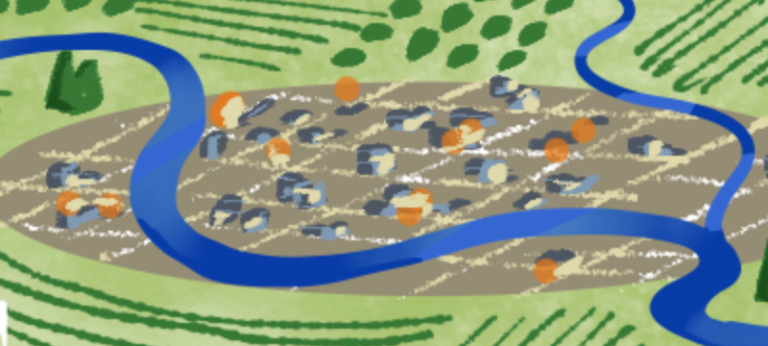

Pine Point Mine, on the south shore of Great Slave Lake in Canada’s Northwest Territories, was a zinc/lead mine active from the late-1960s through the mid-1980s. With additional zinc and lead deposits remaining in hydrothermally-altered dolomite reefs, Pine Point Mining Ltd. (PPML) aims to redefine resources and evaluate the project with implementation of modern mining practices. Current mineral resource locations, spanning nearly 70 by 30 km, comprised of sporadic ore deposits along two principal trends, are accessed through numerous small pits and some underground workings, to depths of approximately 100 to 300 meters. Shallow groundwater, often near the land surface along the northern mineral trend, coupled with the paleokarsitic nature of the reef formations hosting the lead-zinc deposits, makes dewatering and water management critical and costly tasks. In 2021 and 2022, Lynker evaluated previous hydrogeology characterization and modeling efforts described in the Preliminary Engineering Assessment and developed an independent groundwater flow model to assess dewatering needs. Lynker has since refined the model to support the engineering, mine planning, and site-wide water management in the ongoing Feasibility Study and associated environmental permitting studies.

Solution

Lynker, part of a multidisciplinary team led by PPML supported by a variety of consultants, provides critical data and analyses to support engineering, economic, and permitting processes. Our groundwater models developed from assimilating regional gridded datasets, enhanced with focused exploration, geophysics, and aquifer tests, are calibrated to steady-state current conditions and against transient historical dewatering records. Advanced technologies like pore-velocity probes, profile tracer tests, and aquifer pumping tests enable precise data collection to help optimize mining plans and ensure environmental compliance.

These calibrated models inform water-quality simulations for tailings disposal, water management, and regulatory adherence. Particle tracking guides efficient strategies for water and waste management. Reactive solute transport models, based on site-specific experiments and laboratory Kd measurements, predict potential migration of Chemicals Of Concern (COCs), aiding post-closure compliance planning and water quality assessment. This work helps optimize operational and closure plans, aligning economic goals with environmental standards.

Actionable Intelligence

Lynker delivers actionable intelligence by combining advanced groundwater modeling, in-situ hydrogeologic characterization expertise, practical engineering considerations, and environmental analysis. Their refined models predict dewatering sequences, ensuring operational efficiency and regulatory compliance. These simulations also guide in-pit tailings disposal and water management, while reactive transport models anticipate post-closure water quality. Insights gained from Lynker’s analyses and modeling efforts have helped empower the multidisciplinary mine teams to address economic, operational, and environmental challenges effectively.

By integrating cutting-edge hydrogeologic characterization and simulation technologies and proactive planning, Lynker ensures optimized resource utilization and seamless alignment with the mine’s strategic objectives.